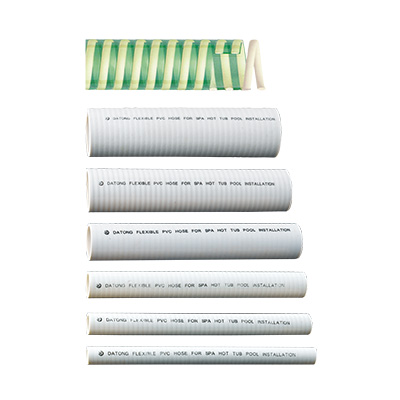

Jetway Flex Massage Whirlpool Nozzle Bathtub System Hottub Spa Hot Tub PVC Hose

Quick Details

● Product Name: Jetway Bathtub Corrugated hose

● Model Number: PVC Hose

● Surface Material: PVC

● Massage Type: Whirlpool massge jet,Combo Massage

● Face: PVC

● Function: Massage Spa for Live

● Usage: Bathroom,Washroom,Outdoor,hotel,Pool

Product Display

Applications

FAQ

1. Q:Are you a factory outlets or trading company?

A:We are a factory outlets.

2. Q:If small order is acceptable? Yes,trial order is welcome!

A:Yes,trial order is welcome!

3. Q:Could you offer us samples?

A:Yes, generally, free sample for 1~2pcs, and the freigt you need to bear.

4. Q:What’s your shipment terms?

A:Generally, if samples, by air or by express; If bigger order by sea.

5. Q:Could you put our logo on the packing?

A:Yes, it is easy to print your logo on the packing.

6. Q:What’s your package?

A:In standard export cartons, but could be designed as your request.

7. Q:What’s your main port of lading?

A:FoShan/GuangZhou/ShenZhen/ShangHai/NingBo.

Packaging and Shipping

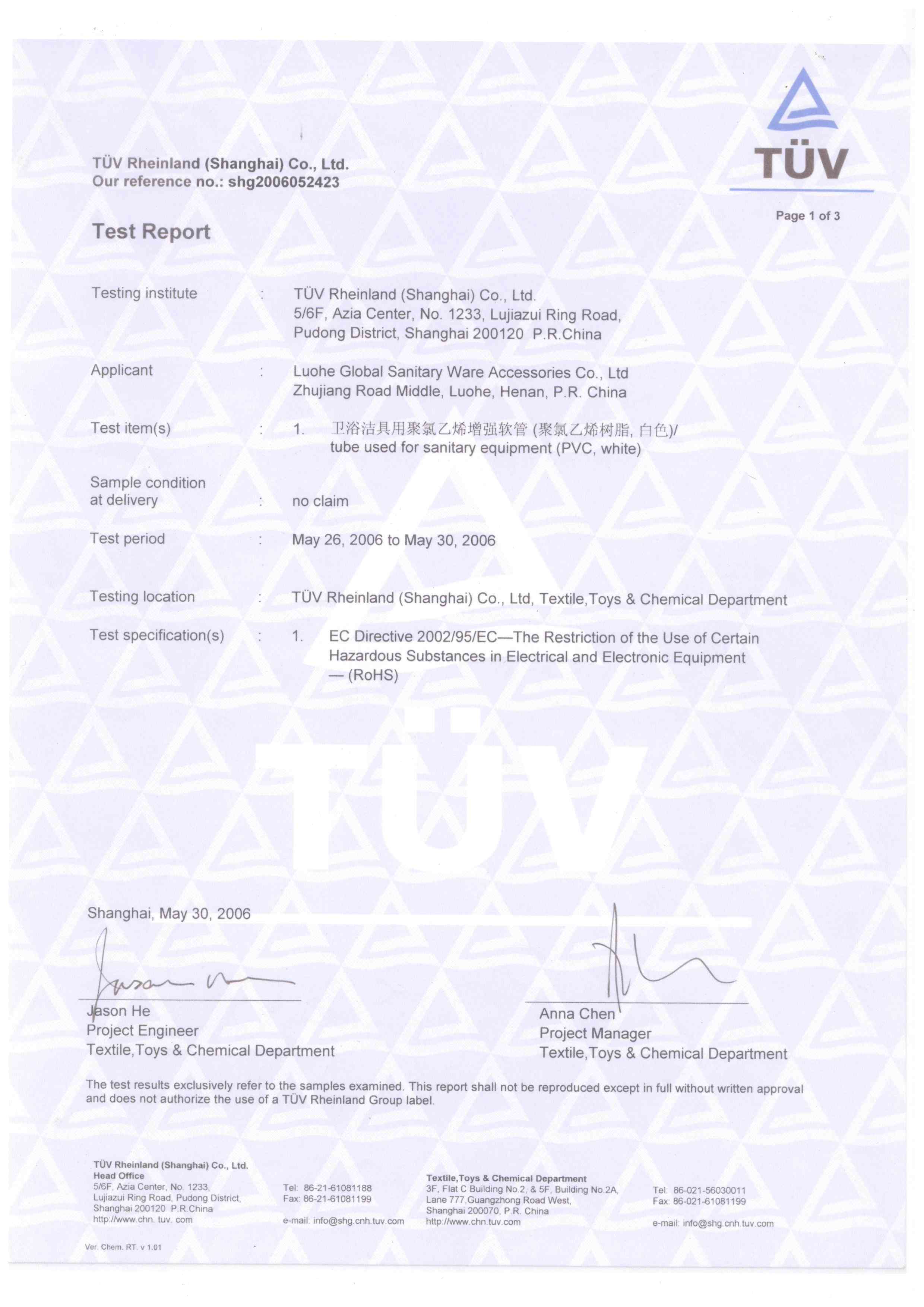

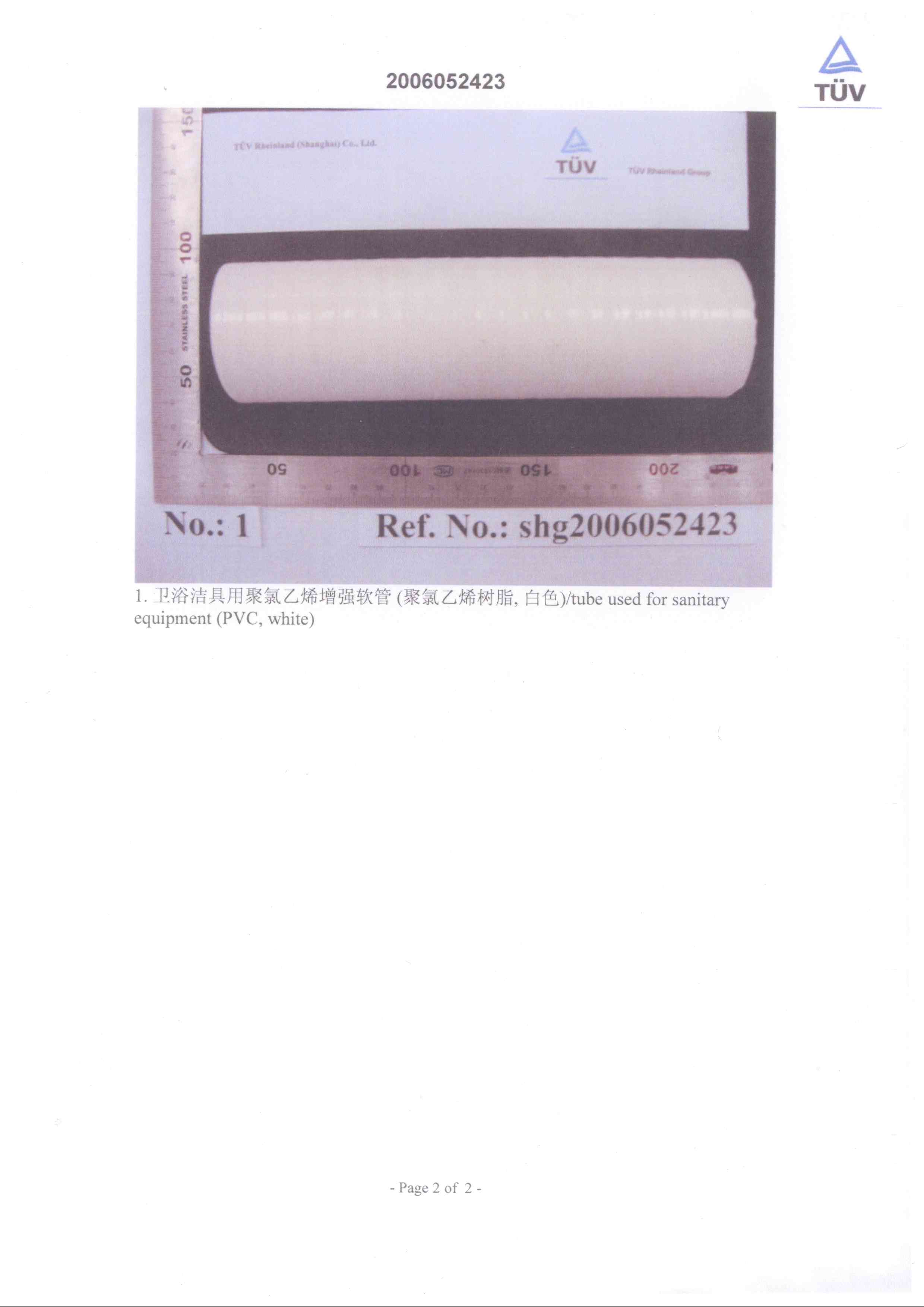

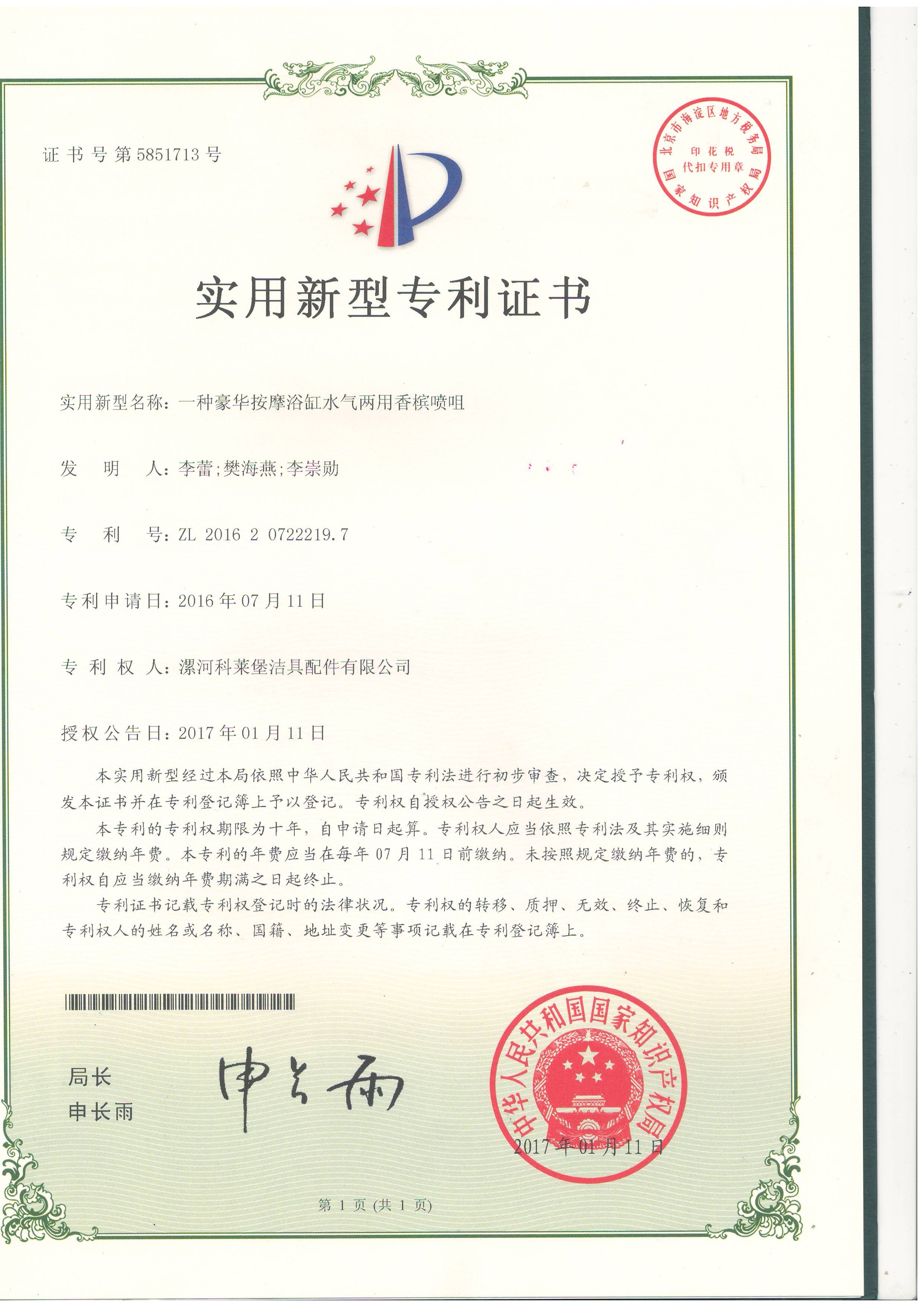

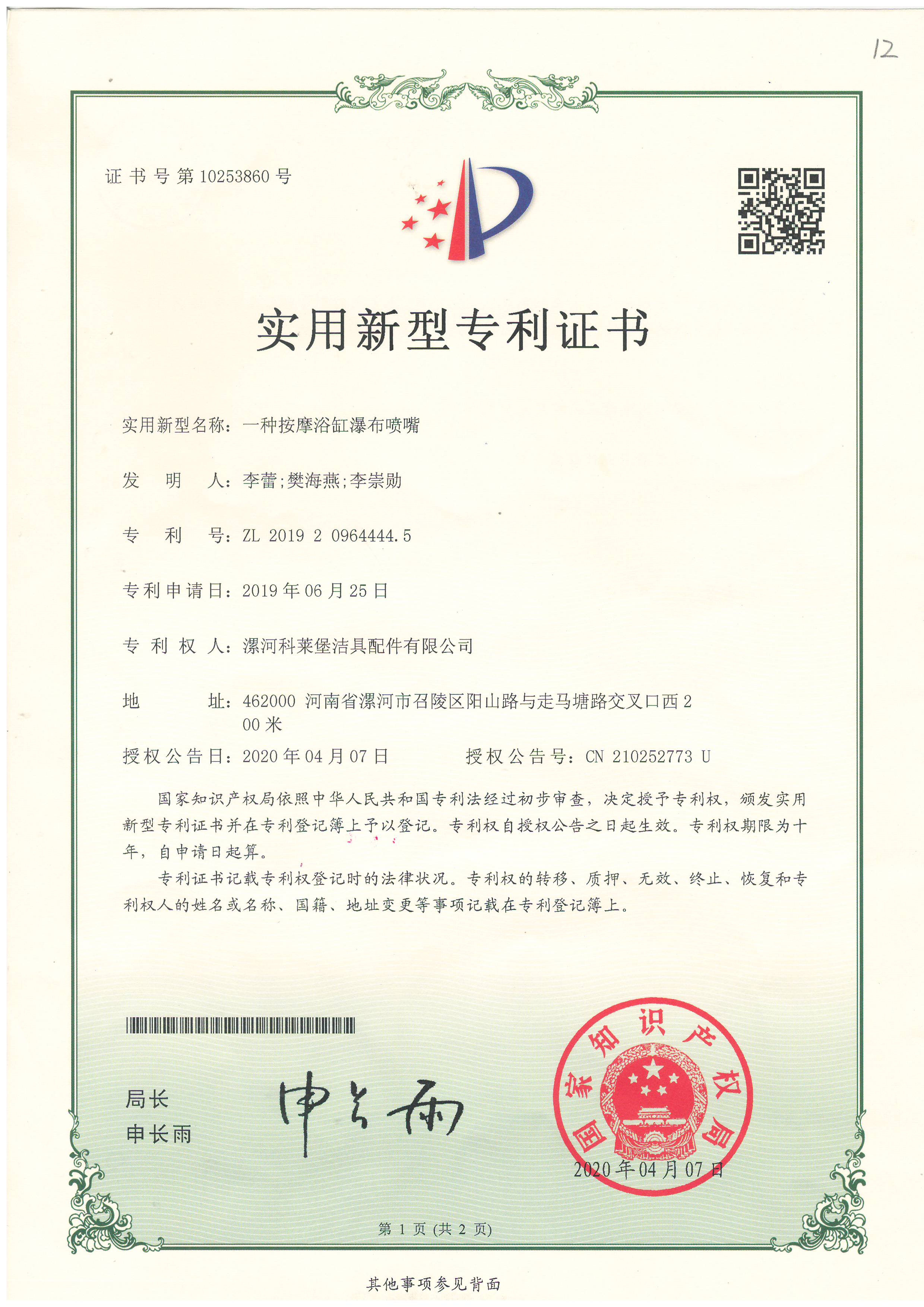

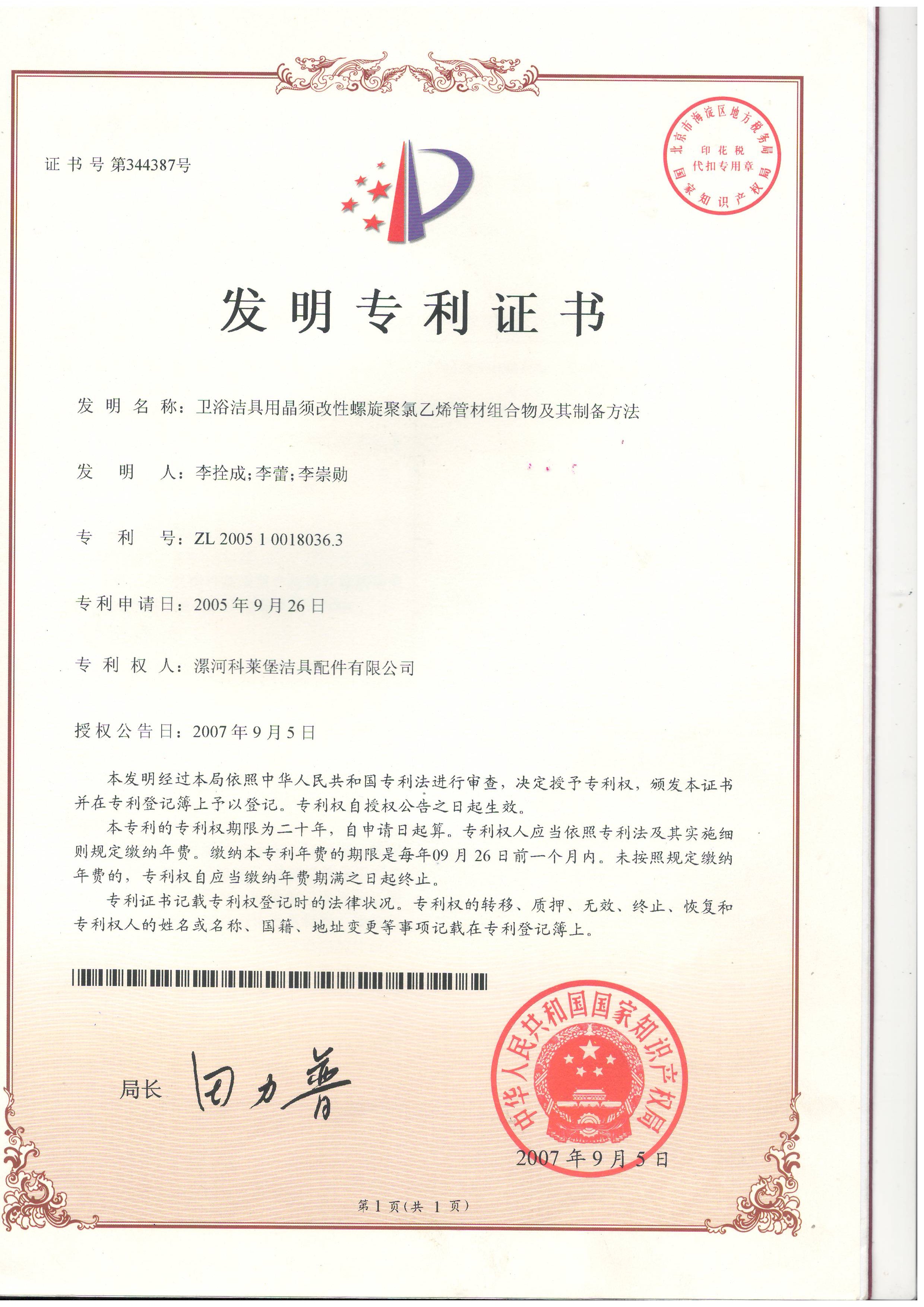

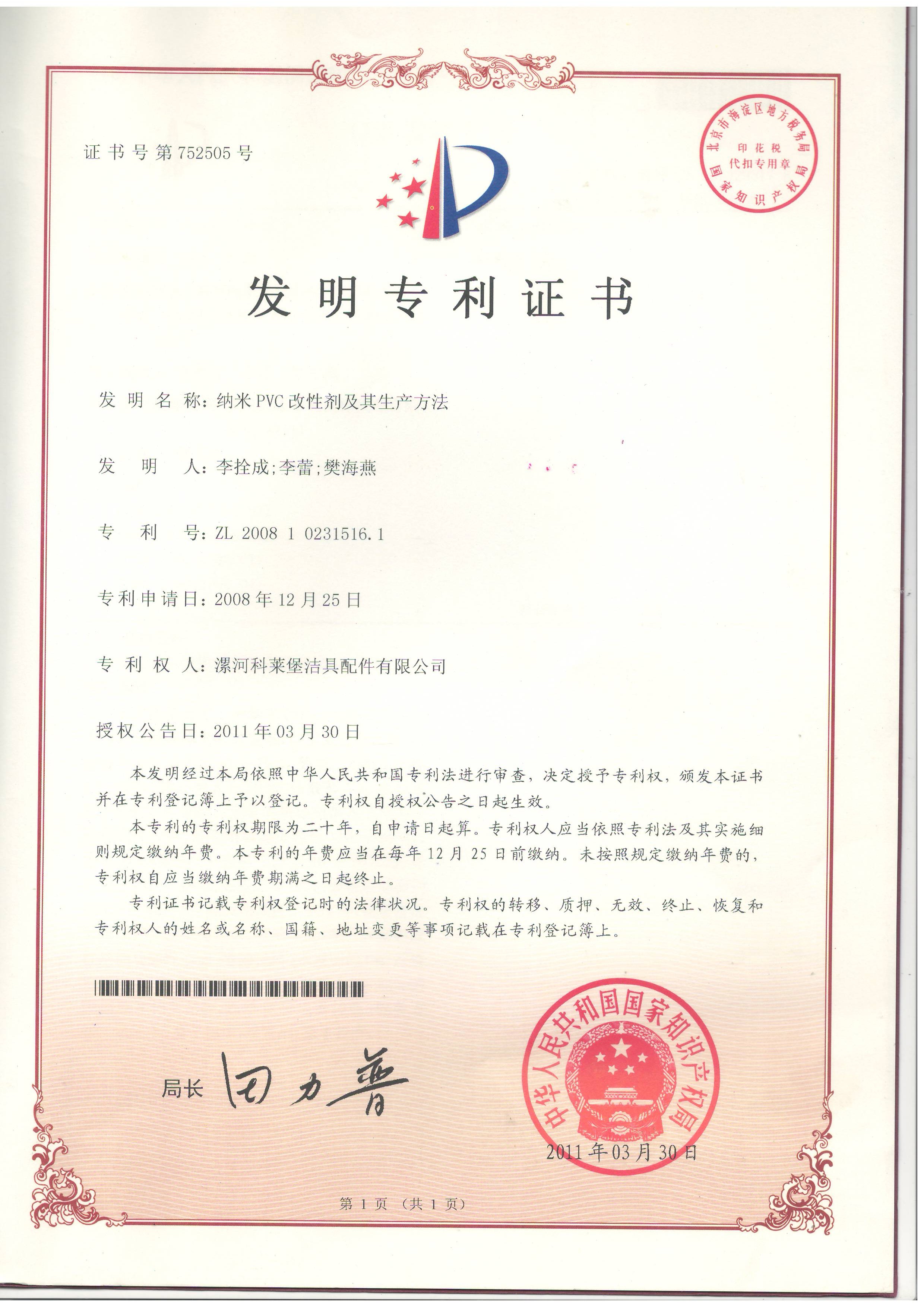

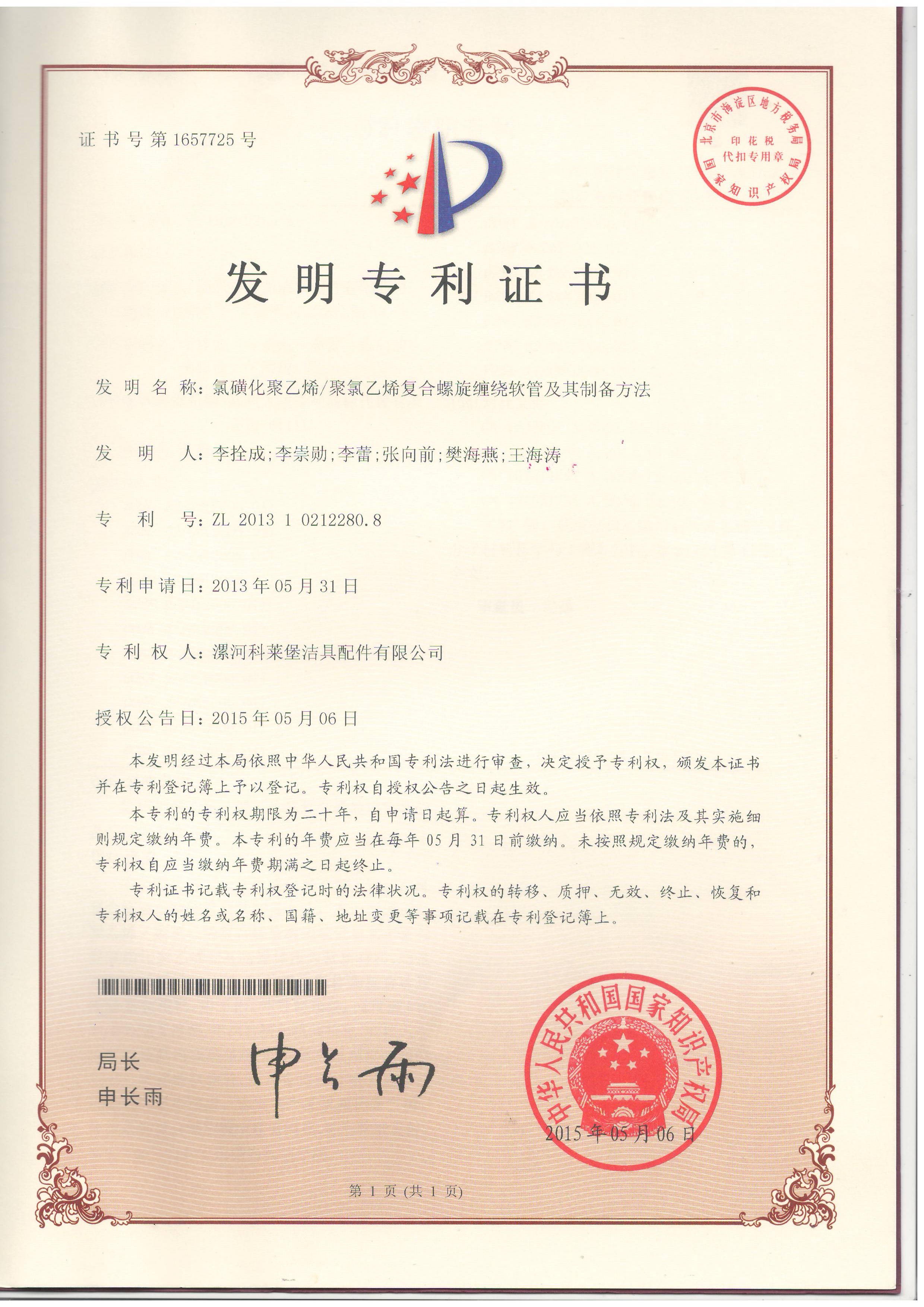

Certificates

1.png)

3-213x300.png)

1.png)

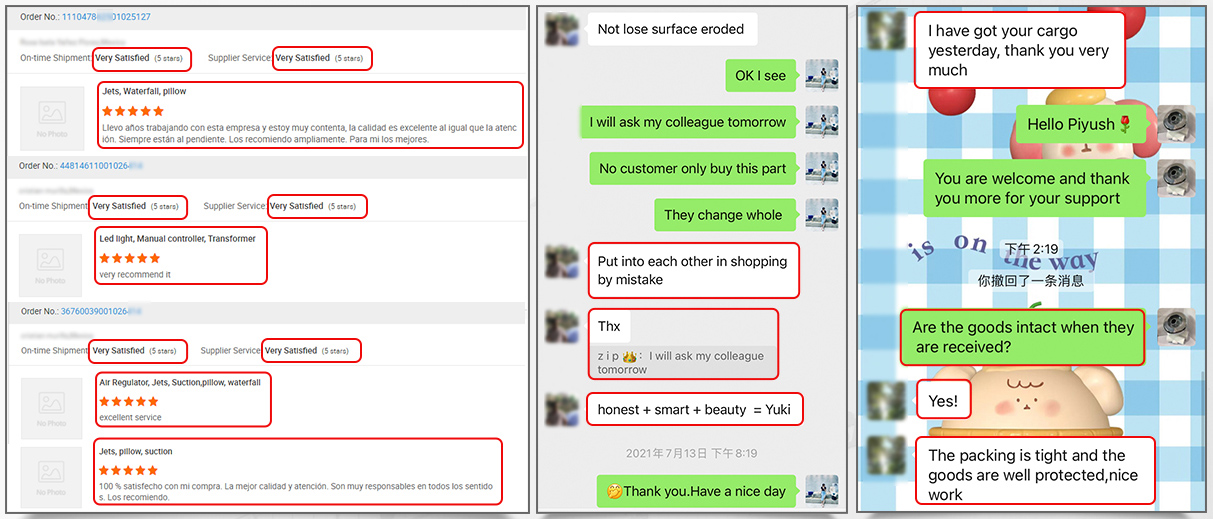

Customer Feedback

Photos of Exhibition Customers Collection

Welcome to Visit Our Factory

News

A guide to understand Flexible

Corrugated Hose

Knowing and Using Flexible Corrugated Hose

Flexible Corrugated Hose a variety of problems common to the industrial and HVAC piping systems. They absorb thermal expansion and contraction, eliminate pipe misalignments and reduce vibration.

Corrugated hose is generally made in bronze, 300 series stainless steel, Monel, Hastalloy, or Inconel.

The primary purpose of corrugated hose is to prevent the transmission of vibration from pumps, compressors, and other power systems to adjacent piping. Care is critical in positioning and connecting. To properly control vibration, the hose must be attached directly to the equipment, perpendicular to the vibration, and with the other end rigidly anchored.

When corrugated hose absorbs thermal growth and contraction, or when it compensates for misalignment, it is important that the hose is relieved of piping weight by adequately supporting the pipe. A thorough analysis of equipment operating conditions and the adjacent piping system is necessary before a suitable metal hose can be selected for a given application.

Usually, the corrosive characteristics of the media being conveyed determines the most suitable metal for the application. Also, pressures and temperature of the media are factors to be considered. Keep in mind that corrosion rates that are acceptable for pipe could be unacceptable for metal hose due to its thinner wall.

Safe containment of pressure and unrestricted passage of fluid are the primary purposes of almost any piping system. This also includes flexible metal hose assemblies. Pressure ratings listed for different hoses by most manufacturers are based on varying assumptions and conditions and must be interpreted properly. The pressure rating for constant, non-pulsating, or non-shock applications are based upon 70F operating temperature. Hose assemblies to be used above 70F must have a reduction factor applied to the stated working pressure.

When pulsating, surge and shock pressures occur, the flexible metal hose assembly should be designed for an operating pressure twice the peak pressure. Installation should be such that there is no slack in the braid sheath when the pressure pulse, surge, or shock occurs.

To obtain the maximum service life from a flexible metal hose the following rules should be followed:

DO NOT TORQUE! Twisting of a metal hose can be eliminated by installing a union or floating flange.

Avoid sharp bends.

Install assemblies at it’s normal length. Avoid compressing.

Install the assembly as close as possible to the equipment or source of the vibration.

Install flexible assemblies at a distance of at least 2-1/2 time the pipe diameter from the centerline of a 90 degree elbow.

Use pipe hangers and supports. The weight of the piping should not be supported by a flexible metal hose assembly

Flexible Corrugated Hose Assembling

Flexible metal hose assemblies provide an effective link between piping, valves, and equipment if

it is selected and applied properly. For good service, make sure the correct hose assembly is installed in the right way. We are here to help you make the right decision on which hose is correct for your application.

The use of the hose planning guide is helpful

S-size of hose and fittings

T-temperature

A-alloy of hose and fittings

M-Motion and application

P-Pressure

E-End fitting attachment

D-Developed length

Flexible Corrugated Hose Assembling meaning:

A corrugated hose is constructed with a bellow of very long length. Fundamentally, the behavior of a corrugated flexible hose is the same as the bellow expansion joint. The flexible hose has to resist the hoop pressure stress, but cannot sustain the longitudinal pressure stress. Also, it has a tendency to squirm under internal pressure. To resist the longitudinal pressure stress and prevent squirm, corrugated hoses are often constructed with braids wrapping around the outside surface as shown in Fig. 4. The braided cover also protects the corrugation from scratch and wear. The braided hose, similar to a tied expansion joint, cannot accommodate any axial movement. On the other hand, the un-braided hose can sustain very small internal pressure.

Due to the lack of a limiting mechanism, a corrugated flexible hose is prone to abuse. It should not be bent beyond its acceptable range. For braided hoses, the situation is even more critical.

Stress Analysis Consideration for Flexible Corrugated Hose

The flexible hose assembly is normally not analysed. In most of the situations, the end displacements from piping or equipment connections are calculated from stress analysis software and those values are transferred to the vendor for their consideration. Accordingly, the hose length and installation space are determined.

Pipe Supporting for optimum Flexible Corrugated Hose

A piping system which utilizes fexible metal hose to absorb pipe movement must be properly anchored and guided to assure correct functioning and maximum service life of the metal hose assembly. The following basic principles should be observed:

Installation considerations for Flexible Corrugated Hose

Flexible Hoses are used to accommodate piping and equipment displacements. Hoses being extremely flexible, installations is very easy. However, a few general precautions should be exercised during installation to avoid hose failures.

- The hose should not be subjected to twisting; Also, the installation should be such that flexing takes place only in the plane of bending.

- The length of the hose should be sufficient to accommodate the offset and movement

- The installation space should be adequate to accommodate the length.

- Sharp bends should be avoided while installing flexible hoses. Technical Data Section of the vendor catalog should be followed to maintain the minimum centerline bend radius for intermittent flexing.

While installing flexible hoses, the allowable minimum bend radius is the most fundamental limitation. For interlocked hoses, the limiting radius depends largely on the clearances between links. It has less to do with the stress and fatigue, so it generally has only one limiting radius for all applications. For corrugated hoses, on the other hand, the limiting radius depends on the stress at the corrugations. For pressure hoses with braided reinforcement, the corrugation stress comes mainly from the bending of the hose. Therefore, the corrugation stresses can be controlled by setting a limitation on the bending. In other words, the installation is acceptable if the hose is not bent beyond the limiting radius. Similar to the situation discussed in the bellow expansion joint, the mode of failure of the hose corrugation is due to fatigue. Therefore, the bend radius limitation depends also on the number of operating cycles expected. Most manufacturers provide two limiting radii, one for static application involving a one-time fit-up installation, and the other for operational movement involving many cycles of intermittent flexing. The whole design and installation process actually ensure that this minimum radius is maintained during the initial layout and throughout the operation.